Custom Poly squeeze tubes are perfect for single or multi use products.

Extend your brands presence with custom printed poly squeeze tubes.

For liquids ranging from lotions, scrubs, masks, creams, gels, waxes, oils as well as industrial products.

- Sizes from 1cc to 10cc

- Tamper evident tips with caps

- FDA approved tubes sold filled or unfilled

- Custom printing available

- Short runs OK

FIPI POLY SQUEEZE TUBES are a smaller version of the widely used toothpaste or cosmetic tube that provides strong product identification when used as customer samples. Designed for sampling and unit dose applications, these tubes are injection molded from LLDPE or PP in a range of sizes from 2cc, 4cc, 8cc and 10cc.

They feature a tamper evident tip, friction fit cap and a smooth seamless body with no parting lines. Decoration is available by high resolution silk screen ink printing around the circumference of the tube. The tubes are available from stock in white or natural, printed or unprinted, filled or unfilled. Lead times are 6 to 8 weeks for a completed decorated and filled tube.

We look forward to hearing from you!

Poly Tube Features

- Manufactured in house using FDA approved, medical-grade

linear low-density polyethylene (LLDPE) or polypropylene (PP) - Smooth, flexible, crack-resistant body tubing with no parting line

- Precision flow, tamper-evident resealable tip

- Volume sizes from 2cc-10cc

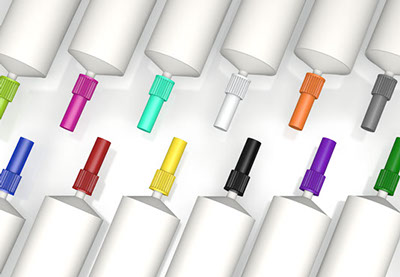

- Caps available in a variety of in-stock and custom colors

- White or natural (translucent) tubing

- Silk-screen printing of text and/or graphics around the tube circumference

- Can accommodate liquids, lubricants, creams, gels lotions, oils, pastes, and alcohol-based products

Materials and Sizes

With three sizes and two materials to choose from, it’s easy to customize Poly Tubes for your specific needs and product application. Both materials are flexible and crack resistant, and injection molding produces a blemish-free surface with no parting lines.

Poly Tubes made from LLDPE (linear low-density polyethylene) can stand up to chemicals and UV light making them ideal for cosmetic, personal care or nutraceutical applications, while polypropylene (PP) is slightly more rigid and resistant to solvents making it a good choice for industrial or automotive products.

All Poly Tubes feature a precision flow, tamper-evident tip that must be cut to open the nozzle. The friction fit cap prevents tip breakage and provides a means to reseal the tube.

Whatever the application, FilitPackit’s Poly Tubes are the perfect solution to your promotional, retail or sample-size packaging needs

Poly tube and cap colors

Both LLDPE (linear low-density polyethylene) or PP (polypropylene) Poly Tubes are available in white or natural (translucent), while the rigid polyproylene caps can be molded to match many Pantone colors.

Printing process

Silk-screen printing of your your logo, graphics and text can be applied around the entire white or translucent tube using any single Pantone matched color. A registration mark is applied during the printing process and after fill and crimping of the end, determines the front and back of the Poly Tube.

Poly tube gallery

Silk-screen printing of your your logo, graphics and text can be applied around the entire white or translucent tube using any single Pantone matched color. A registration mark is applied during the printing process and after fill and crimping of the end, determines the front and back of the Poly Tube.

Or Call Us Today:

310-886-5464